By Nageshwar Haibatpure

New materials are changing the manufacturing industry by providing innovative solutions to complex problems. Carbon Fiber Reinforced Polymer (CFRP), Graphene, Shape Memory Alloys (SMA), Additive Manufacturing

Materials, and Nanomaterials are just a few examples of the many new materials that are revolutionizing the industry.

1) CARBON FIBRE REINFORCED POLYMERS (CFRP) :

CFRP is a composite material made up of carbon fibers and a polymer matrix. Its high strength-to-weight ratio makes it ideal for applications where weight reduction is important, such as in aerospace and automotive industries. It is also ideal for applications where rigidity is important, such as in sports equipment and robotics. CFRP's corrosion resistance makes it ideal for applications in harsh environments, such as marine and chemical industries.

Its fatigue resistance makes it ideal for applications in high-stress environments, such as in aerospace and wind energy. Its low thermal expansion makes it ideal for applications where dimensional stability is important, such as in precision instruments and satellite structures.

2) GRAPHENE :

Graphene is a two-dimensional material made up of carbon atoms

arranged in a honeycomb lattice. Its high strength of over 130 GPa makes it ideal for applications where strength is important, such as in structural engineering and aerospace.

Its optical transparency of up to 97.7% of visible light to pass through makes it useful for

applications in transparent conductive coatings, such as in touchscreens and solar cells. Its flexibility and lightweight make it useful for applications in flexible electronics, such as in

wearable sensors and medical devices. Its high electrical conductivity makes it useful for

applications in the electronics industry, such as in flexible displays and high-speed

transistors.

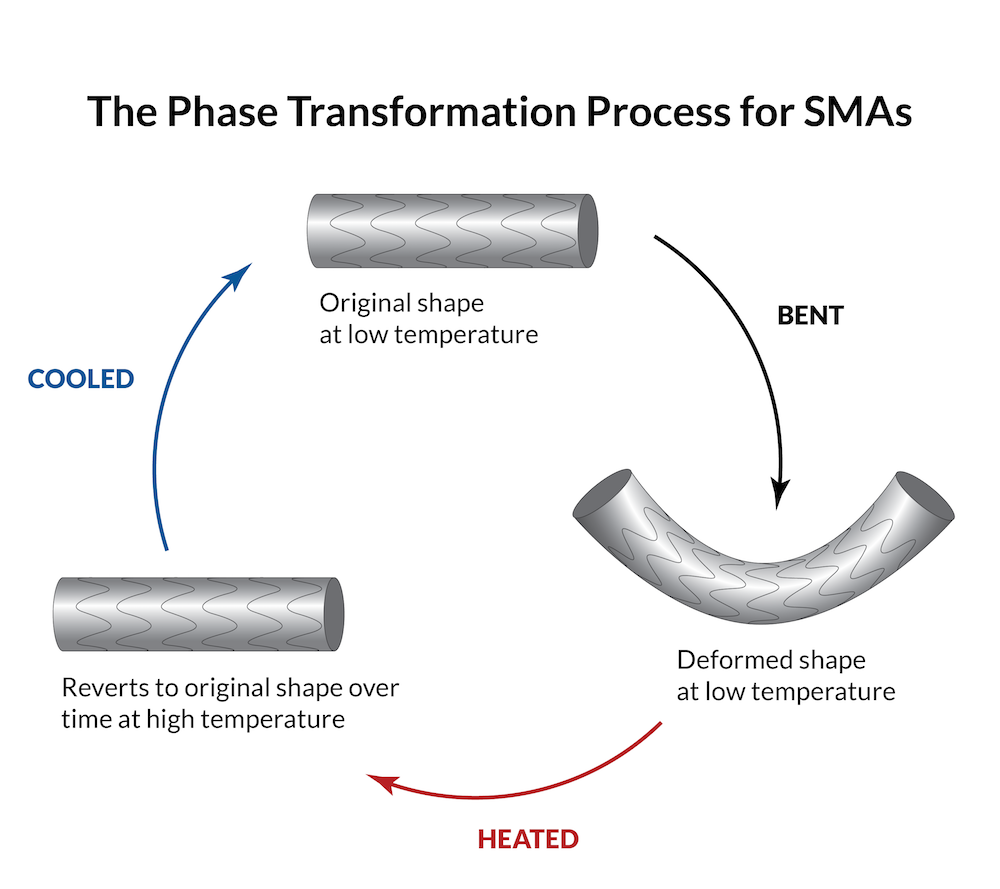

3) SHAPE MEMORY ALLOY:

SMA are a group of metals that can return to their original shape when heated. They have a wide range of applications in the manufacturing industry, including biomedical devices, aerospace components, and actuators. The most common SMAs are based on nickel-titanium (Ni-Ti) alloys, but other materials such as copper-based alloys, iron-based alloys, and gold-cadmium alloys have also been developed. Ni-Ti alloys are preferred due to their unique combination of high shape recovery, good corrosion resistance, and biocompatibility.

The composition of shape memory alloys (SMAs) can vary depending on the specific application and desired properties. The most common SMA is a nickel-titanium (Ni-Ti) alloy, also known as Nitinol, which typically contains 50-55% nickel and 45-50% titanium by

weight.

4) ADDITIVE MANUFACTURING MATERIALS :

Additive manufacturing, also known as 3D printing, is a rapidly growing field in the manufacturing industry. Key technical properties of additive manufacturing materials include layer thickness, melting point, material strength, flexibility, hardness, chemical resistance, and color. The layer thickness determines the resolution of the printed object, while the melting point must be within a specific range for proper printing.

Thermoplastics: These are the most commonly used materials in AM. They are typically used in Fused Deposition Modelling (FDM) and Material Jetting technologies. Common thermoplastics used include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polyethylene terephthalate (PET), and polyamide (nylon).

Metals:

Additive manufacturing can also use metals, which are commonly used in Selective Laser Sintering (SLS), Direct Energy Deposition (DED), and Binder Jetting technologies. Common metal materials used include stainless steel, titanium, aluminum, and cobalt chrome.

Ceramics:

Ceramic materials are often used in stereolithography (SLA) and material jetting technologies. They offer excellent thermal and chemical resistance, making them suitable for high-temperature applications. Common ceramic materials used include zirconia, alumina, and hydroxyapatite.

Composites:

Additive manufacturing can also use composite materials, which are a combination of two or more materials that have different properties. These materials are often used in FDM, SLS, and DED technologies. Common composite materials used include carbon fiber-reinforced polymers, glass fiber-reinforced polymers, and metal-ceramic composites.

Biomaterials:

Additive manufacturing can also use biomaterials, which are materials that are compatible with living tissue and can be used to create medical implants, prosthetics, and other biomedical devices. Common biomaterials used include polycaprolactone (PCL), polyethylene glycol (PEG), and hydrogels. The choice of material for additive manufacturing will depend on the specific application requirements, such as strength, durability, biocompatibility, and cost. Material strength and flexibility play a role in determining if the printed object is functional or a prototype. Hardness and chemical resistance determine how the printed object will react to wear and tear and chemical exposure. Color can be important for aesthetic reasons or for color-coding parts.

5) NANO MATERIALS :

Nanomaterial are materials with at least one dimension in the Nano scale range (1-100 nanometers). They have size-dependent properties, mechanical properties, chemical reactivity, and thermal conductivity. Nanomaterial can have superior mechanical properties compared to bulk materials, such as the exceptional tensile strength of carbon nanotubes. The high surface area and reactivity of nanomaterials can lead to their increased chemical reactivity, which can be exploited for applications such as catalysis, sensing, and drug delivery. Nanomaterials can exhibit superior thermal conductivity compared to bulk materials due to their small size and high surface area.

Types of Nano-Materials :

Nanomaterial can be broadly classified into two categories: organic and inorganic.

Organic nanomaterial :

These types of nanomaterial are materials that have at least one dimension in the nanometer range and are made up of carbon-based compounds. They exhibit unique physical, chemical, and biological properties due to their small size and can be synthesized through various methods, such as self-assembly, chemical vapors deposition, and sol-gel techniques. Some examples of organic nanomaterial include fullerenes, carbon nanotubes, graphene, dendrites, and liposomes.

Inorganic nanomaterial :

Inorganic Nano-materials are particles or structures with at least one dimension less than 100 nanometers made of inorganic materials such as metals, metal oxides, semiconductors, ceramics, and composites. They have unique properties such as high surface area, reactivity, mechanical and thermal properties, and electrical conductivity. These properties make them useful in various fields such as electronics, energy, medicine, and environmental science. Inorganic Nano-materials can be synthesized by several methods such as sol-gel, precipitation, hydrothermal, and chemical vapor deposition.

Applications of Nano-Materials :

Nanomaterial have a wide range of applications in various fields. Here are some examples:

Electronics: Nanomaterial are being used to develop more efficient and compact electronic devices. Carbon nanotubes, graphene, and other nanomaterial are being investigated as potential alternatives to traditional silicon-based electronics.

Biomedical : Nanomaterial are being used to develop new and more effective diagnostic and therapeutic tools. For example, gold nanoparticles are being used in cancer diagnostics and drug delivery, while carbon nanotubes and graphene are being investigated as potential drug delivery vehicles.

In conclusion, new materials are revolutionizing the manufacturing industry by providing innovative solutions to complex problems. CFRP, Graphene, SMA, Additive Manufacturing Materials, and Nanomaterials are just a few examples of the many new materials that are changing the way we manufacture products. These materials have properties that make them ideal for specific applications, and their use is expanding rapidly as more research is done on their properties and applications. The development and use of new materials are expected to continue to drive innovation and improve the efficiency, performance, and sustainability of the manufacturing industry.